Seals Eastern, Inc.

Steam Resistant Rubber

Seals, Gaskets, and O-rings for Steam and Hot Water Service.

Tel: 732-747-9200

Tel: 732-747-9200

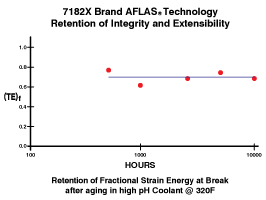

Seals Eastern, Inc. has decades of field service and

10,000 hour test data that validate the stability of formulated

7182TM Aflas in hot aqueous environments. Examining the

retention of tensile strength (integrity) and the retention of

elongation (extensibility) reveals a sealing material capable of

long-term service in high temperature steam and hot aqueous fluids.

(To learn about this approach to evaluating elastomers read our

technical paper "Thermal Stability of BPAF and TAIC Cured Fluoroelastomers")

Seals Eastern, Inc. has decades of field service and

10,000 hour test data that validate the stability of formulated

7182TM Aflas in hot aqueous environments. Examining the

retention of tensile strength (integrity) and the retention of

elongation (extensibility) reveals a sealing material capable of

long-term service in high temperature steam and hot aqueous fluids.

(To learn about this approach to evaluating elastomers read our

technical paper "Thermal Stability of BPAF and TAIC Cured Fluoroelastomers")

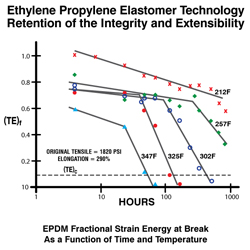

Steam and hot water service seals, gaskets, and o-rings have

traditionally been made of EPDM. However, at temperatures exceeding

100C, EPDM seals quickly fail (see graph at right). Auda and Hazleton

of Exxon Chemicals Co., Elastomers Technology Division (an historic

supplier of EPDM elastomer) published a study entitled "Ethylene

Propylene Elastomer Technology for Improved High Temperature

Serviceability" regarding the life expectancy of EPDM in hot

applications. In dry heat temperatures exceeding 100C (212F), their

study demonstrated a sudden and dramatic loss of integrity (retained

tensile) and extensibility (retained elongation). The failure

mechanism is oxidation. However, a Y-267 type EP is an exception to

this rule. In HTHP steam where oxygen is absent, a Y-267 EP such as

our compound 7204 performs exceptionally well.

Steam and hot water service seals, gaskets, and o-rings have

traditionally been made of EPDM. However, at temperatures exceeding

100C, EPDM seals quickly fail (see graph at right). Auda and Hazleton

of Exxon Chemicals Co., Elastomers Technology Division (an historic

supplier of EPDM elastomer) published a study entitled "Ethylene

Propylene Elastomer Technology for Improved High Temperature

Serviceability" regarding the life expectancy of EPDM in hot

applications. In dry heat temperatures exceeding 100C (212F), their

study demonstrated a sudden and dramatic loss of integrity (retained

tensile) and extensibility (retained elongation). The failure

mechanism is oxidation. However, a Y-267 type EP is an exception to

this rule. In HTHP steam where oxygen is absent, a Y-267 EP such as

our compound 7204 performs exceptionally well.

In the 1970’s, Seals Eastern evaluated the aging of a high fluorine content, low VF2 containing grade of FKM class fluoroelastomer in steam. Temperatures and time frames exceeding the capability of EPDM were studied. Multiple AS568-214 o-rings of the fluorelastomer were aged in a time sequence up to 12,000-hours in 175C (347F) continuous steam. The saturated steam / hot water was a controlled pH of 7.0-7.5. Usually, a slightly basic pH is maintained to prevent corrosion in all such steam systems. The effects of steam on an FKM elastomer are depicted below. The failure mechanism is dehydrohalogenation despite the low level of VF2 in the elastomer.

850 Hours |

1,700 Hours |

2,700 Hours |

3,700 Hours |

4,700 Hours |

5,800 Hours |

6,700 Hours |

9,200 Hours |

11,100 Hours |

There is no tendency of this FEPM class rubber to oxidize like a standard EPDM or dehydrohalogenate like a VF2 containing fluoroelastomer (FKM). We offer three compounds that have proven to be best-in-class over the past three decades. Contact us for longer seal life in your steam applications.

| FEPM | Compound | Duro | Description |

|---|---|---|---|

| 7182D | 80 | Formulated AFLAS ® for Steam, Hydrocarbons, Acids, and Bases and other chemical families. | |

| 7182X | 80 | Formulated AFLAS ® for Steam, Hydrocarbons, Acids, and Bases and other chemical families. Ultra-low compression set. | |

| 7182B | 90 | Formulated AFLAS ® for Steam, Hydrocarbons, Acids, and Bases and other chemical families. Resists extrusion. | |

| EP | Compound | Duro | Description |

| 7204 | 90 | Y-267 type EP for geothermal steam and HTHP steam service. |

| 1. | Elastomers for Steam Service |

| 2. | Thermal Stability of BPAF and TAIC Cured Fluoroelastomers (in super-heated water) |

Premium Quality Seals...

For a Cleaner, Safer, More Reliable World.TM